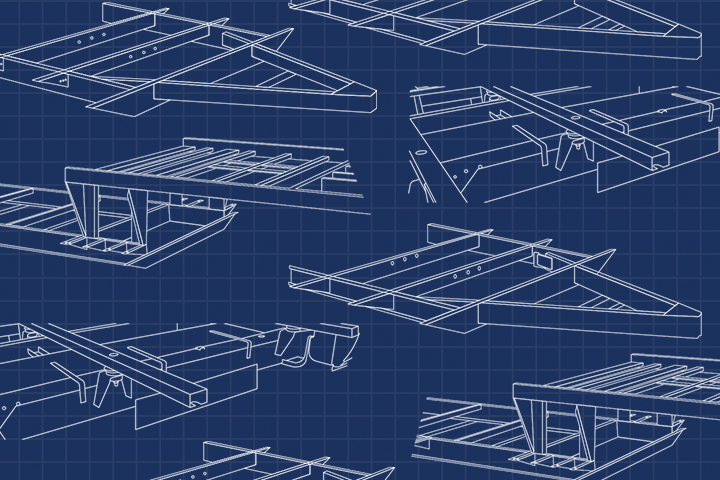

Any structure’s foundation is crucial to its integrity or, in other words, how long it will satisfactorily serve its intended purpose. An RV is no different. Of course, the poured concrete used for buildings won’t work for mobile RVs. Metal frames are counted on to help the RV endure the rigors of the road and elements—and they’re not all created equal.

At Jayco, we put extra effort into the design of our frames. While other manufacturers often rely on stock frames, we refuse to settle for cookie-cutter solutions. Every Jayco RV is built on a custom frame, designed and sized specifically to best support each unit.

Let’s run down the different frames we use and what makes them superior.

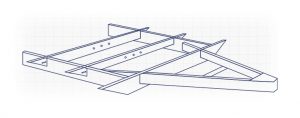

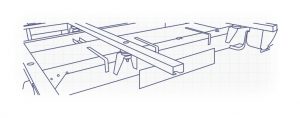

Lightweight Travel Trailer Frame

While the vast majority of our assembly is carried out by expert craftsmen, we turn to our trusted partners at Norco and their advanced fabrication equipment for help building the frames for most of our lightweight trailers. Robotic production makes it possible to cut and weld each Norco® NextGen frame to our exact specification with repeatable precision and strength that can’t be matched.

While the vast majority of our assembly is carried out by expert craftsmen, we turn to our trusted partners at Norco and their advanced fabrication equipment for help building the frames for most of our lightweight trailers. Robotic production makes it possible to cut and weld each Norco® NextGen frame to our exact specification with repeatable precision and strength that can’t be matched.

- This frame features the industry’s strongest strength-to-weight ratio thanks to high-strength, low-alloy sheet steel, an interlocking design and huck bolts that provide up to 10x the fatigue strength of conventional fasteners.

- To help better support the walls, the frame’s outriggers are spaced just 4-6 feet apart (vs. the usual 6-8 feet) and span the full width of the trailer instead of stopping short.

- An integrated A-frame runs through the main frame, preventing the hitch from buckling like competing tack-welded frames can.

- An electrically-coated finish adds resistance to corrosion.

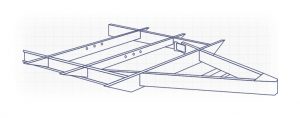

Large Travel Trailer Frame

The supremely strong combination of I-Class cambered I-beams, molded, one-piece construction and rugged structural-steel materials make this frame design our choice for our larger travel trailers.

The supremely strong combination of I-Class cambered I-beams, molded, one-piece construction and rugged structural-steel materials make this frame design our choice for our larger travel trailers.

- One-piece beams reduce twisting and warping that can occur at the welded seams of the three-piece beams often used by competitors.

- To help better support the walls, the frame’s outriggers are spaced just 4-6 feet apart (vs. the usual 6-8 feet) and span the full width of the trailer instead of stopping short.

- An integrated A-frame runs through the main frame, preventing the hitch from buckling like competing tack-welded frames can.

Fifth Wheel Frame

The unique form of the fifth wheel frame requires extra attention to detail. It’s why we use one-of-a-kind designs and materials where it matters most for a stronger, more durable frame.

The unique form of the fifth wheel frame requires extra attention to detail. It’s why we use one-of-a-kind designs and materials where it matters most for a stronger, more durable frame.

- Instead of just attaching the underbelly to the bottom of the frame, L-brackets create a channel within the frame that secure the underbelly cover for tightly sealed insulation and a sag-free protection barrier.

- One-piece beams reduce twisting and warping that can occur at the welded seams of the three-piece beams often used by competitors.

- To help better support the walls, the frame’s outriggers are spaced just 4-6 feet apart (vs. the usual 6-8 feet) and span the full width of the trailer instead of stopping short.

- A larger, 2" x 6" box tube perimeter frame over the high-stress truck bed area better supports the sidewalls and resists torque.

- We reinforce storage areas with both vertical and horizontal cross members. We reinforce models that feature drop frame storage with a larger, thicker monster beam below the main I-beam.

Here’s a quick tip for fifth wheel shoppers. To spot a potentially weak frame, look for a vertical plastic strip on the bedroom sidewalls. This seam typically means the bedroom walls aren’t built on a thick perimeter frame; this support seam is added to compensate for expansion joints.

Class C Motorhome Frame

When it comes to our Class C motorhomes, we know how important precision can be in creating a smooth ride. The same holds true in creating a solid foundation. As with our trailers, we don’t settle for the standard frame pattern provided with each chassis.

When it comes to our Class C motorhomes, we know how important precision can be in creating a smooth ride. The same holds true in creating a solid foundation. As with our trailers, we don’t settle for the standard frame pattern provided with each chassis.

- We build on a one-piece, laser-sheared, tight-fit frame with extra heat shielding.

- We use full-width trusses that extend to the edge of the sidewalls to better support the weight of the wall.

- For added safety, each truss design undergoes a pull test to make sure it is strong enough to support the coach.

- Our entry steps are secured to the frame instead of the floor.

- Finally, we balance the driveshaft on the line to reduce vibrations, ultimately protecting your foundation.

Class A Motorhome Frames

https://www.youtube.com/watch?v=PXFYEd7IC5M

- In addition to the Ford® F53 chassis on which we build our gas models, the Class A lineup offers a foundation no else can.

- The Embark diesel pusher is built exclusively on the Spartan K1 360 chassis. Measuring in at just 37 feet in length, it’s one of the shortest, easiest and most comfortable Class A diesel motorhomes on the market.

If you’d like to learn more about our frames, you can watch this quick video to see more and hear directly from some of our product directors.

More RV Construction Resources

Would you like more information on the construction of Jayco RVs? Go behind the scenes to see how a Jayco RV is built and find answers to questions about common RV build materials.

RV Tracker: How A Jayco RV is Built